For the highest hygiene standards

Cables and connectors for the food and beverage industry

For the highest hygiene standards

Cables and connectors for the food and beverage industry

5G, or not to be? Here, LAPP provides some details on evolving options for ensuring optimum connectivity for robotic solutions.

Cables and plug connections have to withstand a great deal, but this is especially true for the food and beverage industry, where the right choice of material is crucial.

With Christmas coming up fast, don't risk being caught out on critical parts for your shut down maintenance. Be Ready for your scheduled plant shut down maintenance with LAPP.

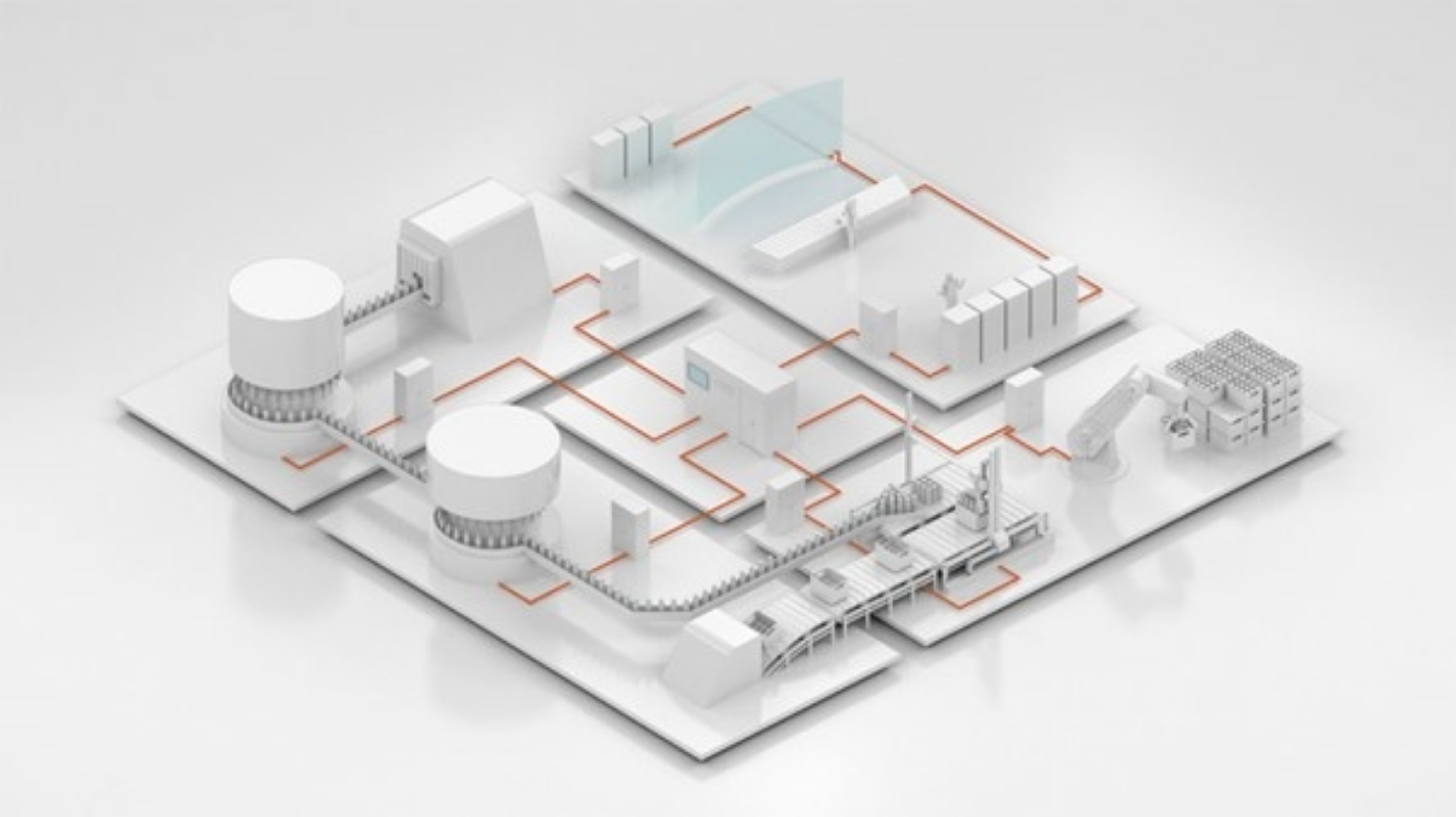

The ROBUST series consists of cable and connector solutions for power, control and data transmission, as well as bus, sensor and Ethernet connections. Thanks to their chemical resistance, as well as being highly ozone, UV and weather resistant in compliance with EN 50396 and HD 605 S2 our ROBUST products are certified to be suitable for wet cleaning in the food and beverage industry.

Hygiene takes top priority when it comes to processing food and beverages. Production facilities should therefore be designed according to the principles of Hygienic Design. That means cables, connectors and housing bushings also play an important role.

In 1978 Oskar Lapp registered the patent for SKINTOP®, a cable gland for easily securing cables. SKINTOP® experienced immediate success on the market, gaining a reputation as an extremely effective cable gland.

Selecting the right choice of material for connection systems. There are msny differences in the materials with advantages and disadvantages depending on the application. Therefore, one should know exactly which attributes of a material are suitable.

The globally proven SKINTOP® cable gland system will be highlighted by LAPP Australia at AUSPACK March 26-29 as a range that cuts cable system assembly time while offering optimised protection indoors, outdoors and in hot or cold conditions.

Mon-Fri 7:00am - 5:00pm

Australia