Selecting the right choice of material for connection systems. There are msny differences in the materials with advantages and disadvantages depending on the application. Therefore, one should know exactly which attributes of a material are suitable.

Knowledge

German Chancellor Dr. Angela Merkel and Swedish Prime Minister Stefan Löfven visited the LAPP stand in Hall 11 on their tour of the halls of the Hannover Messe 2019. There they were impressed by the latest digital developments of the Stuttgart-based company.

A company that is bridging a gap in the Australian market for quality European manufactured cable products backed by dedicated local support has been well received for its service, expertise and extensive range at its AUSPACK debut in Melbourne last month (March 26-29). Global cables, connectors and accessories leader, LAPP, established a permanent Australian subsidiary in 2018, and has since been steadily expanding the total number of high-quality products available locally.

LAPP is further expanding its industrial Ethernet systems portfolio with a greater range of its globally proven ETHERLINE® ACCESS brand of active network components.

The globally proven SKINTOP® cable gland system will be highlighted by LAPP Australia at AUSPACK March 26-29 as a range that cuts cable system assembly time while offering optimised protection indoors, outdoors and in hot or cold conditions.

The new LAPP Australia operation of one the world’s leading providers of branded cable and connector systems, LAPP, will debut at AUSPACK 2019 in March with a range of quality technologies vital to integrated electrical, process and automation engineering solutions.

Opening a LAPP Credit Account is Easy. Take advantage of the many great benefits of becoming a LAPP credit account holder.

Quick-connect circular connectors are becoming an ever more popular solution for cabling in servo drives: Plug in, turn the housing to the right, done. LAPP has developed a robust and practical locking mechanism.

During the festive season LAPP Australia's office will be closed from 24th December 2019 and re-opening on 6th January 2020.

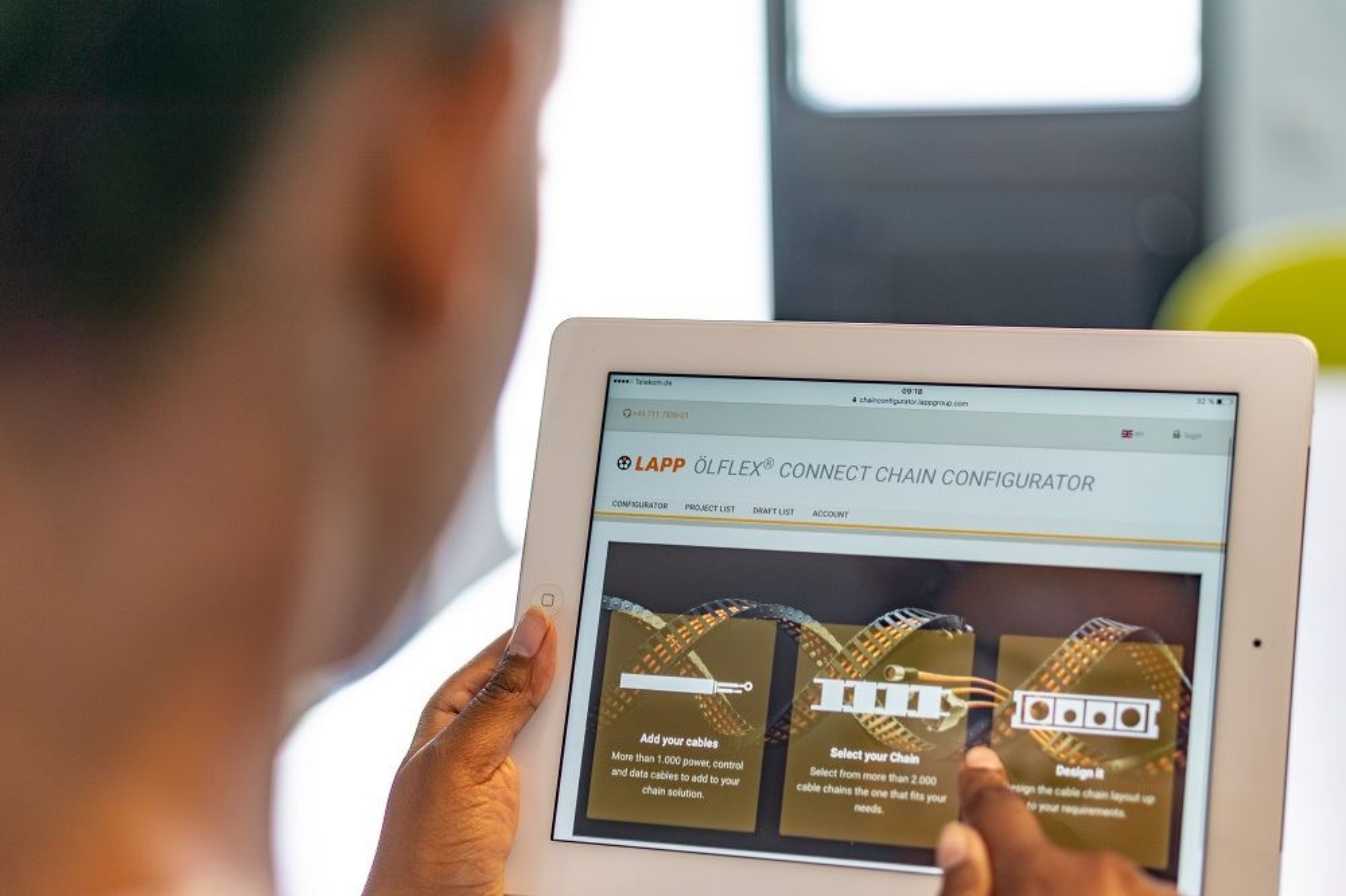

The new ÖLFLEX® CONNECT CHAIN configurator: You can use it to digitally engineer a power chain online with just a few clicks of the mouse. Configuring power chains is no longer a complicated task as this tool makes it easy, even for less experienced users. The ÖLFLEX® CONNECT CHAIN configurator automatically switches off all error sources and always finds the best solution.