As a leading provider of integrated solutions and branded products in the field of cable and connection technology, LAPP has a special responsibility: all over the world, other companies depend on the Stuttgart-based family-owned company to deliver high-quality connection solutions reliably and on time. The technological and logistical requirements of customers are high and constantly increasing. At the same time, LAPP is also challenged when it comes to sustainability, because here, too, the demands of legislators, society and industry are constantly increasing.

Thanks to its pronounced culture of innovation, which is characterised by proactive action and maximum customer orientation, LAPP is able to identify the most relevant sustainability issues in the context of connection solutions and develop convincing answers.

Use of renewable and low-emission raw materials

Renewable raw materials instead of fossil raw materials are important for reducing CO2 emissions: Plastics are part of our society today because they are very resistant and hard to replace. To this end, LAPP is increasingly researching the use of bioplastics of plant origin that are suitable for use in cable sheathing. It is important here that the properties of the bio-based sheathing material do not differ from those of the previous cable sheathing. Thus, LAPP supplies an outer sheath for its connection solutions that combines both: more sustainable production from renewable raw materials and reliable resistance to external influences on the product.

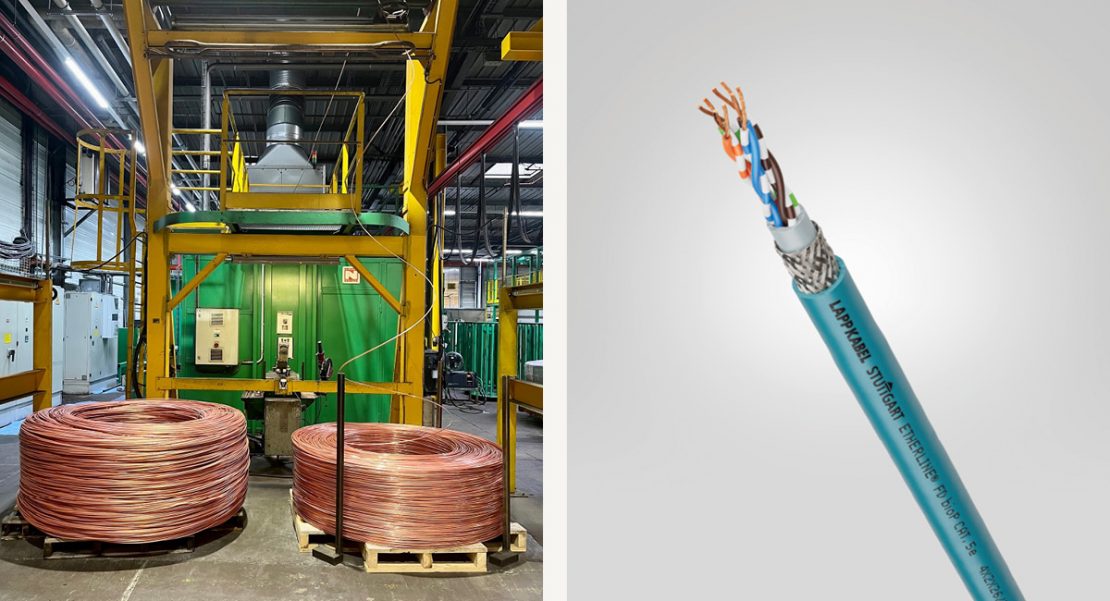

The story continues inside the cable: copper is an important material for cables because it is conductive and heat-resistant. However, mining copper produces large amounts of CO2. In the CUPRUM project (Latin for copper), LAPP is therefore analysing companies in its supply chain and identifying sustainable sources of copper. LAPP is working closely with its suppliers to reduce the CO2 footprint of copper, including through recycling.

Reduction of the CO2 footprint

According to the German Environment Agency, the industrial sector emitted more than 100 million tonnes of CO2-equivalent greenhouse gases in 2023. In order to achieve a sustainable industry with reduced greenhouse gas emissions, companies must set themselves clear goals and strategies. LAPP wants to reduce its carbon footprint by 2025 – on the company and product side, verifiably and transparently. To this end, the company provides its customers with verified emissions data for its products. And it is researching products, such as the prototype of the ÖLFLEX® CLASSIC FD 810 control cable in a carbon footprint-reduced version. Other factors include sustainable supplier management, the generation and use of green electricity for its own processes and internal recycling.

Efficiency-driven logistics

Not only products have to become more sustainable, but also their journey to the customer. By optimising internal factory transport and using energy-efficient logistics partners, LAPP has succeeded in reducing the total number of kilometres travelled and significantly reducing CO2 emissions. Furthermore, electric forklift trucks are used almost exclusively in all logistics and service centres.

LAPP has also optimised the efficiency of the logistics hub in Hanover, Germany, to the highest possible level with innovative solutions and optimised processes.

Alternative and recycled materials for packaging and transport reduce plastic, waste and CO2 emissions. Cardboard waste is used as filling and packaging material. Cable drums are reprocessed wherever possible. In addition, the logistics centre relies on purchased electricity from renewable energy sources, but also from its own sources – one example of this is self-sufficient charging stations for e-vehicles that are powered by solar and wind energy. And last but not least, the favourable location in Hanover leads to short delivery distances, which not only reduces CO2 emissions but also delivery times.</>

Prepare regulatory requirements in advance

There is hardly any other area in which so many new regulatory requirements arise as in sustainability. From the 2025/2026 fiscal year, LAPP will have to officially report on its sustainability performance for the first time. The company still has a lot to do. This includes training global personnel in reporting on social and ecological key figures.

However, the effort is worthwhile – after all, companies, and especially those like LAPP, will continue to have to take responsibility for the environment and society. For the family-owned company, this is a matter close to its heart, and one in which LAPP continues to work tirelessly, despite all the successes it has already achieved.