Built for Australian Industry

When unplanned downtime is not an option, cable performance matters. The ÖLFLEX® motor and servo cable range supports reliable power, control, and feedback transmission for electric drive systems used across Australian manufacturing, mining, materials handling, and automation.

Designed for compatibility with common drive platforms, these cables support stable operation in demanding industrial environments.

Motor, Servo, Encoder, and Hybrid Cables Explained

Motor connection cables

Designed for three-phase motor power supply. Low electrical losses and robust insulation support consistent torque and thermal stability under load.

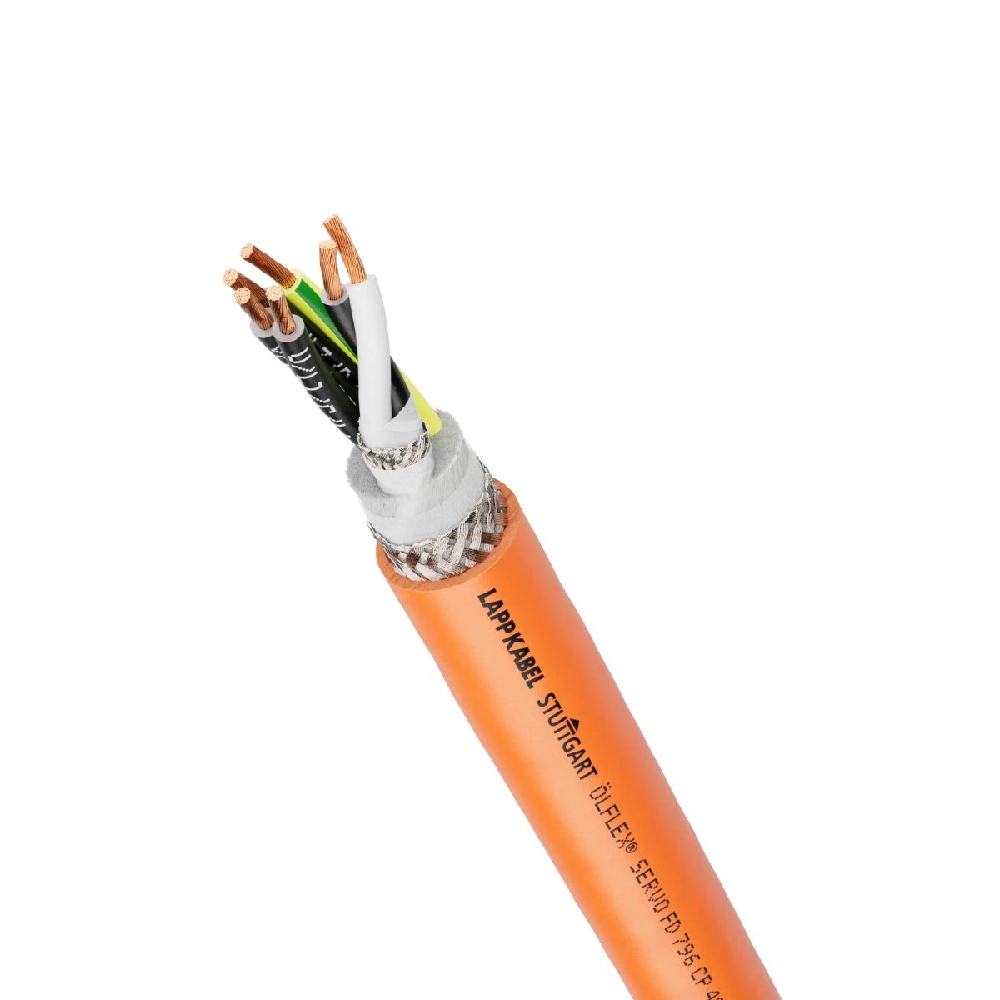

Servo cables

Used for servo drives where accurate speed, torque, and position control are required. Suitable for CNC machinery, robotics, and automated production lines.

Encoder cables

Provide high-quality feedback signals from encoders and resolvers to the drive or controller. Screening options support reliable data transmission in electrically noisy environments.

Hybrid cables

Combine motor power and encoder signals in a single cable. This reduces installation time, cable routing complexity, and space requirements in drag chains and cabinets.

Typical Applications in Australia

- Conveyor positioning and automated handling systems in mining.

- Packaging, filling, and sorting lines in food and beverage plants.

- Automated storage and retrieval systems in logistics and warehousing.

- Motion control and feedback systems in wind turbine installations.

Installation Types Covered

- Fixed installation cables for control panels and static machinery.

- High-flex cables for cable chains and continuously moving equipment, rated for millions of flex cycles.

All variants are suitable for integration with widely used drive systems from major manufacturers and align with Australian electrical requirements.

Key Technical Features

- Oil-resistant outer sheaths for industrial conditions

- Halogen-free options for improved fire behaviour

- UV-resistant designs for outdoor installations

- Screened constructions for EMC-sensitive environments

- Temperature ranges from -40°C to +90°C, depending on type

- Voltage ratings covering standard 0.6/1 kV motor applications and low-voltage control circuits

Selecting the Right Cable

Ask three practical questions:

- What voltage and current does the drive require?

- Is the cable fixed or subject to continuous movement?

- What environmental conditions are present, such as oil, UV, or mechanical stress?

Servo systems typically use 4-core or hybrid cable designs. Standard three-phase motors commonly require 3 or 4 power cores. Encoder feedback can be integrated using hybrid constructions to simplify installation.

If specifications are unclear, our technical team can help match the cable to your drive system and installation requirements.

Local Stock, Fast Supply

All motor and servo cables are stocked in Australia for fast dispatch. No extended lead times or overseas delays.

Browse the full range online or contact our technical sales team for application-specific advice.