L & R Kältetechnik container innovations for Covid Vaccines include LAPP OLFLEX® HEAT 260SC cables engineered for the most extreme application requirements.

![]()

Cables and connector systems are a vital link in high-performance refrigeration systems required by industries such as food and beverage, chemical, medical, scientific and advanced logistics and shipping companies.

Failures could not only cost valuable product, but even lives where temperature ranges of minus 70 degrees Celsius and more are involved, says LAPP Australia General Manager, Simon Pullinger.

LAPP Australia’s parent company, the global LAPP cables, connector and automation technology leader – with 4,650 employees and markets in more than 100 countries – was recently involved with a customer’s refrigerated container innovation which overcomes temperature challenges at both ends of the extreme temperatures scale.

The customer is L & R Kältetechnik, which produces refrigerating systems for exceptionally low temperatures encountered by chemical and pharmaceutical industries. L & R was asked by the German manufacturer of a Covid vaccine, Biontech, to assist it with the bulk transportation of millions of doses a time of its vaccine following approval for its widespread use.

The vaccine has to be stored at -70 degrees Celsius, and only tolerates standard refrigerators for a short time before being administered.

Biontech supplies the vaccine in boxes that act like large Thermos flasks, keeping the content cool for several days, says LAPP. But what can logistics companies do if they want to send the vaccine in containers by air or ship, where transportation takes longer?

Any fault with electrics in extreme applications could cost lives, with the rubber seal between the lock and storage chamber freezing immediately, leaving any person inside trapped and in mortal danger.

![]()

L&R came up with idea of taking a conventional shipping container with a length of 20 or 40 feet and installing a refrigeration chamber, including cooling and even an autonomous emergency power supply with a diesel generator or liquid nitrogen – and ensuring everything has a backup in case of failure.

A standard 40-foot-long container can hold a 40 cubic metre refrigeration chamber with a temperature of minus 80° and a preliminary chamber at minus 20°, which acts as a low temperature airlock. The storage area is estimated to have a capacity of up to 3.5 million vaccine doses.

For such low temperatures, transport companies normally have to use dozens of laboratory deep-freeze cabinets, which are not only expensive, but require significantly more power and space.

Watch Video: Cool solution for the world made in Germany (© L&R Kältetechnik)

Hot And Cold

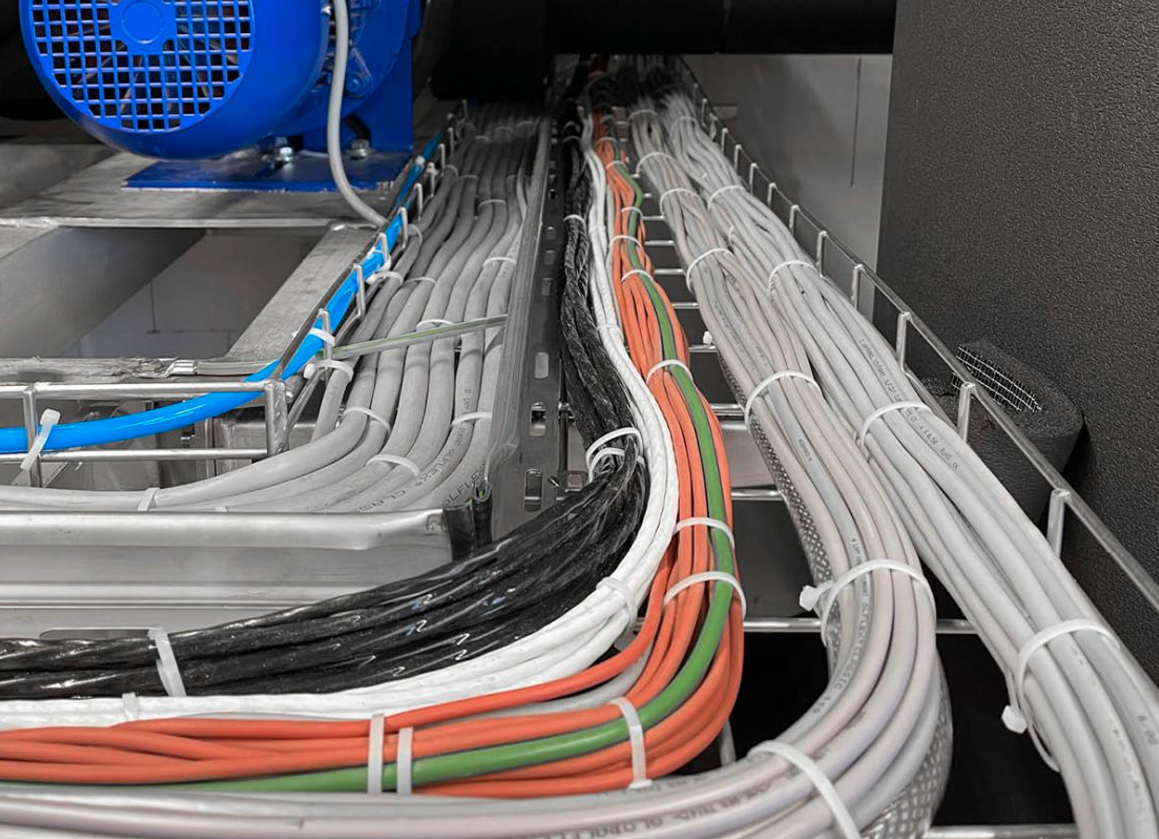

The cables used to make this container application possible have to withstand harsh condition in the form of extreme temperatures, both cold and hot. For example, the refrigerant flows through the evaporator at a temperature of minus 90°C. Fans ensure that the heat is dissipated.

To prevent their electric motors from freezing, the bearings are heated. The two compressors have a power of 20 kilowatts each, and currents of 40 amps flow through the ÖLFLEX Classic 110 cabling (one of the LAPP cables L&R Kältetechnik uses exclusively for its innovations, drawing on specialised product from the same ranges available in Australia). Directly on the diesel generator, the temperature can rise to over 100°C – positive that is.

In the icy storage compartment, meanwhile, the temperature can be as cold as minus 100° in some places, ÖLFLEX HEAT cables with a PTFE sheath are installed. With these, L&R Kältetechnik is really playing it safe, as the ÖLFLEX® HEAT 260 SC is suitable for the most extreme application requirements. It is robust, chemical resistant and space-saving for use in machine and equipment construction at -190°C to +260°C.

Heating for lights and door frame

In addition to the power cables in the cooling system, the container also contains signal transmission cables, for example from the temperature sensor that controls the frequency converter and thus the compressor. In addition, the operator can connect a data cable into the control cabinet at a customer interface.

There are also some cables that are not responsible for cooling, but for heating. When you switch on a light at home, it should not be covered so that the heat can dissipate. In the vaccine store, the problem is precisely the reverse. In this case, the LED light strips actually need to be heated because otherwise they could simply fail.

And the rubber seal on the door between the lock and the storage chamber would freeze immediately, leaving any person inside trapped and quickly in mortal danger. As a result, there is heating on the door frame and door contacts to monitor when someone enters the chamber. The person present in the low temperature section of the container has to press a button regularly.

If there is no signal, the person may have fallen unconscious and an alarm is triggered. Any fault in the electrics could cost lives, which is why L&R Kältetechnik is playing it safe with cables from LAPP. “In our quotations we not only specify the properties of the cables but also that they are ÖLFLEX cables from LAPP and which type.” “That really makes a difference for our customers,” says Christoph Wiemer, Head of Special Systems Sales at L&R Kältetechnik

Incidentally, minus 80° Celsius is not the coldest system from L&R Kältetechnik, which produces refrigeration chambers operating down to minus 110°, including some for therapeutic applications.

“Cold saunas” are becoming increasingly popular, to regenerate the body but also to reduce stress and relieve pain. At -110°C, users only need 2-3 minutes per session to achieve their individual objectives.

![]()