What is industrial communication?

Essentially it is your key to future competitiveness! The future of manufacturing is 5G, Wifi, Industrial Ethernet, and IIoT. With our industrial-suited, robust high-quality products for the intelligent control of PLC, sensors and actuators, we support you in transforming your factory into a Smart Factory.

Industrial Ethernet is the successor of the conventional Ethernet, known from the office and is primarily used for data communication in industrial production. There are good reasons for this: It offers a seamless network infrastructure and that in real time. The areas of application are diverse and reach from the field and control level to the MES/ERP level, the Manufacturing Execution System (MES) for order coordination and Enterprise Resource Planning (ERP) for material planning. Industrial Ethernet technology includes a large address space for participants. With IPV6 addressing, networks with practically unlimited numbers of participants can be implemented. Large data volumes can be transmitted simultaneously and at high speeds of up to 40 Gbit/s via copper. This also applies to data communication over long distances: Distances of up to 80 km can be bridged using fiber optic cables. Networks can be easily expanded and segmented via switches and routers.

What is the difference between Ethernet and Industrial Ethernet?

Ethernet originally comes from office communication and is usually connected in the office area using star topology. Industrial Ethernet was developed from this basic technology. For industrial applications, however, real-time capability and reliability are of decisive importance. For this reason, components and protocols have been developed that provide time predictable behavior and redundancy mechanisms to prevent failures. Data communication is therefore not interrupted and failures and downtimes are minimized. Industrial Ethernet - as the name says - is used in the industrial area (field level) and must therefore work reliably even under extreme conditions. Our Industrial Ethernet products therefore not only withstand extreme temperatures, dust and humidity, they are also resistant to chemical or physical stress.

Industrial communication from a single source.

From the sensor, actuator and control level to the ERP-system – we work together with you to realize entire network cabling solutions for the reliable transmission of the highest data volumes. We provide the highest quality products because each individual component is required to maintain machine up-time and avoid costly downtime. Therefore, our connection solutions are ideally suited for demanding conditions and offer maximum reliability under chemical, mechanical, and thermal stress.

LAPP advantages at a glance

- Products for all common protocol standards

- Protocol-independent expert advice

- High-performance copper and fiber optic cables

- Complete solutions from one source: cables, connectors, patchcords & switches

Industrial Ethernet vs. Fieldbus

At LAPP you get the best out of two worlds!

Industrial Ethernet is a young technology that has clear advantages over classic fieldbus systems including offering a seamless network infrastructure from the sensor/actuator level via the control level to the office level – a seamless, transparent communication.

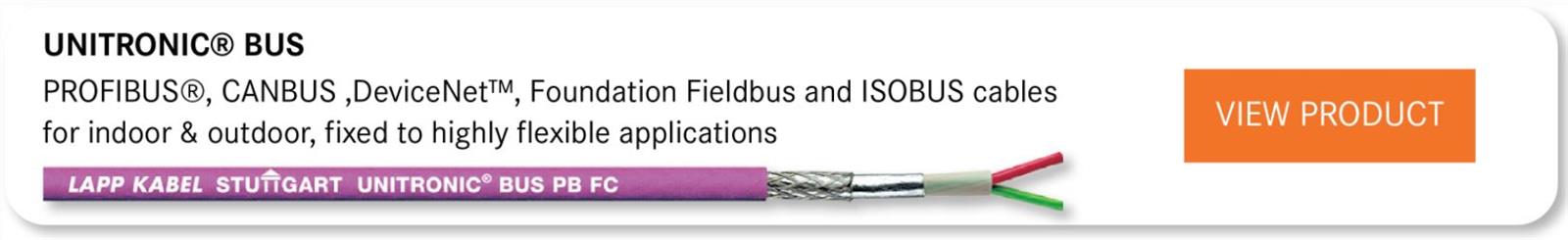

Fieldbus technology is suitable to connect complex devices at the field and control levels. It is characterized by lower installation costs and simple expansion of sensors and actuators. PROFIBUS® is therefore suitable for the transport of small data volumes and is limited to a small number of stations.

PROFINET® offers an address range for an almost unlimited number of devices and can send and receive significantly larger data volumes at high speed (10 Gbit/s compared to 12 Mbit/s for fieldbuses).

Explore our industrial communication e-training and keep track of topics around automation, Ethernet, and Fieldbus!

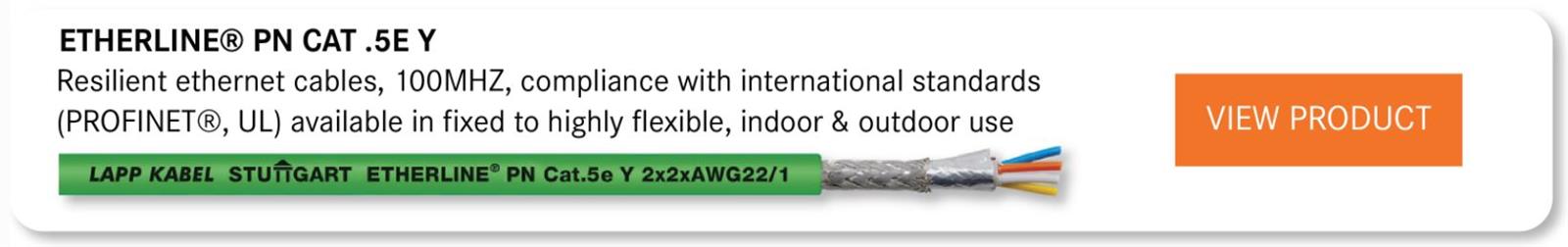

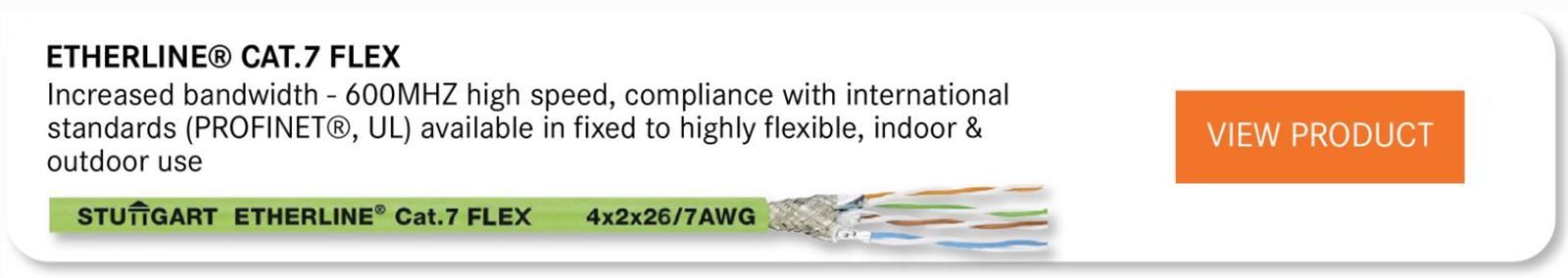

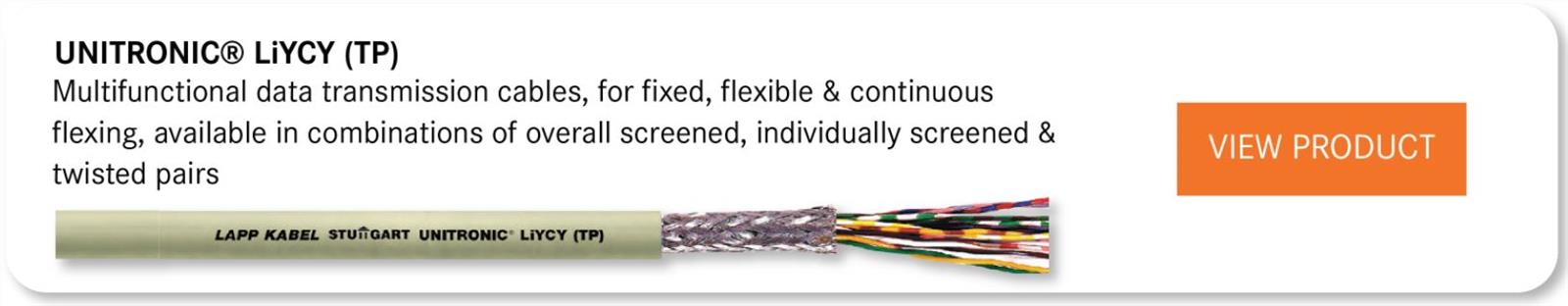

Cables designed for Industrial Communication: