Connection solutions for railway technology from LAPP

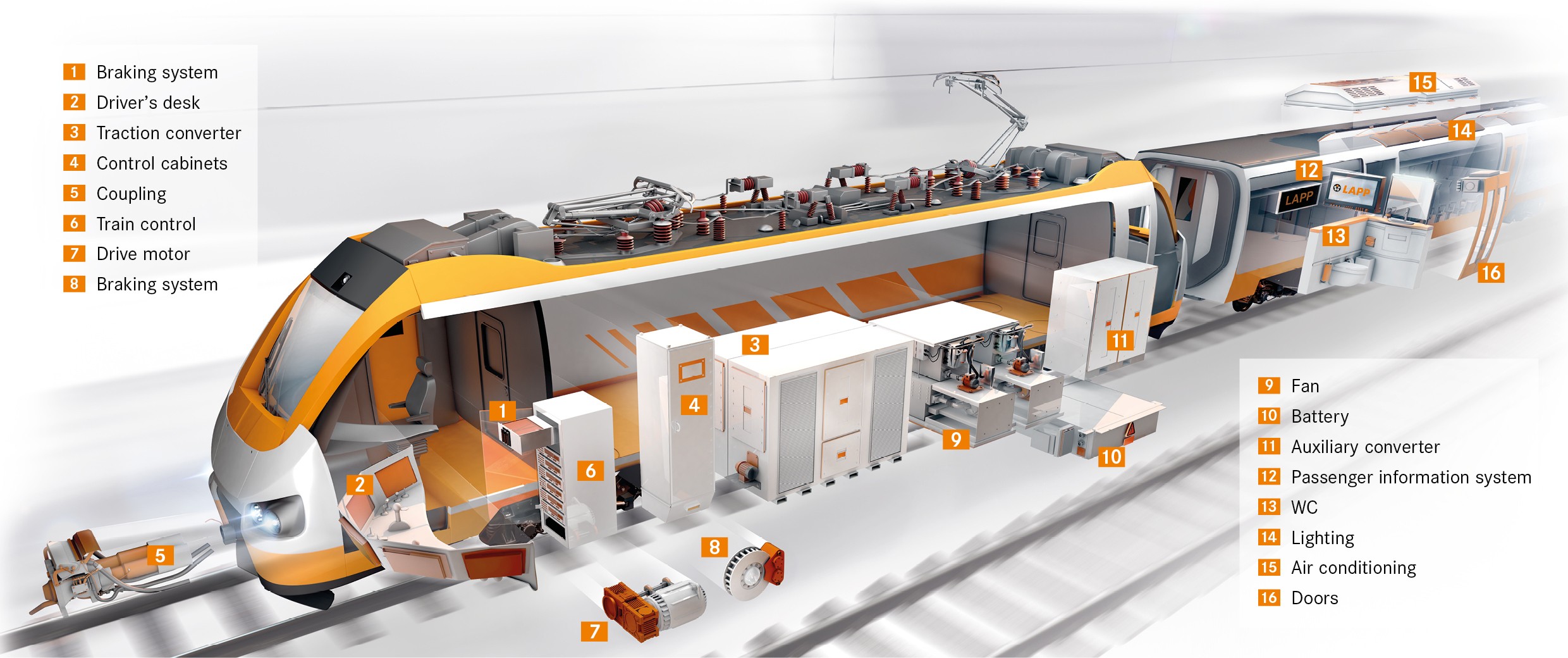

The right solution for your needs: power supply, control functions and data transmission for rolling stock

Increasing urbanisation and progressive digitalisation are constantly placing new demands on railway technology. The demand for transport systems is growing with increasing population density. And with it the expectations for safety and reliability of rail transport. Cables and wires for railways must comply with special safety regulations and fulfil functions in order to be approved for rail vehicles. With the extensive portfolio for railway technology from LAPP, you receive tested and certified system solutions from a single source.

What special requirements must cables and wires for rail transport meet?

The high availability and smooth operation of rail vehicles depends largely on the cables and wires used. Whether power supply, data transmission or the control system: reliable connection solutions enable smooth operation and safe transport.

Cables and wiresfor rail vehicles must have special properties in order to be approved for rail transport. The unrestricted safety of passengers and personnel is the decisive factor. For this reason, fire protection in rail vehicles is treated with great importance and regulated in Europe in the DIN EN 45545-2. Materials and components for rail vehicles are subject to clear specifications.

According to DIN EN 45545-2, railway cables and connection solutions must have the following essential properties:

- Halogen-free

- Flame retardant

- Self-extinguishing

In the event of a fire, the products used do not contribute to fire propagation and prevent additional damage to people and materials. In addition, the products have to be able to withstand external influences such as stone chipping, torsion or strong vibration waves that permanently affect them.

Extreme climatic conditions during operation also place high demands on the material properties of cables, wires, cable glands and connectors. Most components must therefore withstand temperatures ranging from -50° to +120°C.

Why LAPP products for rail transport?

At LAPP we know what is important when it comes to connection solutions for rail transport. Our LAPP portfolio for railway technology meets a variety of standards and safety requirements.

Advantages of LAPP products at a glance:

-

Own electron beam crosslinking facility and IRIS / TS 22163 certification at the Lapp Korea LLC production site

-

Cable types according to EN standards and other standards

-

Many years of experience in the rolling stock market

-

Shortest delivery times - high stock availability

-

Small minimum order quantities and presentations

-

Complete connection solutions from one source

Our product solutions for rail transport

- ÖLFLEX® TRAIN: Electron beam cross-linked cables for increased requirements in the railway sector according to EN 50264 for 300V, 600V 1.8kV and 3.6kV, EN 50306 300V and EN 50382 1.8kV and 3.6kV

- UNITRONIC® TRAIN: Bus cables - MVB and WTB - Electron beam cross-linked for increased requirements in the railway sector

- ETHERLINE® TRAIN: Ethernet cables electron beam cross-linked for increased requirements in the railway sector

- SKINTOP® MS-HF-M: The brass cable gland for cable diameters up to 98mm, for areas with high demands on mechanical and chemical stability, for railway applications. Meets the requirements of EN 45545-2, HL3 and EN 45545-3, E30. Also available as EMC versions.

- SKINTOP® ST-HF-M: The halogen-free, metric plastic cable gland for railway applications, HL3, extremely flame-retardant and self-extinguishing, high functional safety

- SILVYN® HFX-V0: The liquid-tight, chemical-resistant, low fume protection hose with single-folded metal protection sleeve and PUR outer jacket

- EPIC® MH MODULAR SYSTEM: High flexibility through any combination of inserts in one connector. EPIC® MH System is pluggable with the market standard. For use in railway applications: EN 45545-2, HL1, HL2 and HL3.